Printing Help & FAQs

Need extra help with your printing job? We’ve put together answers to some of the most common printing FAQ. Remember, if you ever want to talk to a real person, we’re always here waiting for your call!

Want to Talk to Someone Instead?

We’ve got real experts waiting to hear your ideas and make them happen. Contact us! We’re here to help magnetize your brand and maximize your marketing 5 days a week 8am-5pm MST.

Talk to a Real PersonHow to Compress Files for Upload

If you use a Mac or have more than 4 files to upload it would be best to upload them as a single compressed file by following these instructions.

Take all the files for the job and put them in a single folder whose name is your company name.

Compress the folder as a .zip file using Winzip or PK Zip if it’s a Windows platform file. Use Stuffit on the Macintosh platform and BinHex encode the file so that your file will retain its resource fork and arrive happily with its icons intact.

If your files are extremely large you may want to compress them into several archives such as companyname-1.zip, companyname-2.zip, etc. Sometimes it is easier to successfully upload 3 25MB files than it is to upload a single 75MB file.

You can download the programs from the links below.

Zip Info

Please write your order number on your package and disk. You’ll see the order number on the order confirmation page after you hit the “Send Order” button below. Include on your disk only the file(s) you want printed. Your files can be compressed as a zip or stuffit archive. Flash drives are automatically returned. CDs and DVDs are only returned if you request it on the ordering page or indicate it with your disk.

File Formats

We gladly accept all popular Mac and PC file formats, including any version of:

Microsoft Publisher, Word, Excel, Home Publishing, Powerpoint, PhotoDraw, Works, Picture It

Quark XPress

Adobe Pagemaker, InDesign, Illustrator, Photoshop, FrameMaker, Acrobat, Photoshop Elements

Corel DRAW, PHOTO-PAINT, WordPerfect, Lotus, Ventura, Bryce, Quattro Pro

Macromedia Freehand, Fireworks

Deneba Canvas

Serif PagePlus, PhotoPlus, DrawPlus

Claris Works

Apple Works

Broderbund The Printshop (version 15, 20-22), PrintMaster, Calendar Creator

Plus these: Open Office, Greeting Card Factory, Art Explosion Publisher and More

What if I want to change something on my order after I’ve placed it or approved the proof?

We require an electronic “paper trail” for all changes made after your initial order is placed.You may make changes to such things as quantity, shipping method, or shipping address by going to the Change Order Request page. Please note that some changes cannot be made after certain stages in the production process — for instance, the quantity cannot be changed once your job has been printed.

Will I always receive exactly the quantity I order?

Most of the time, we ship you slightly more than you ordered, free of charge. On occasion, we ship slightly fewer pieces than you ordered. Printing industry trade standards allow for underages of up to 5%. If you plan to send your print order to a mailing list or need a guaranteed quantity, we recommend that you order 5% over the minimum quantity you need.

Where can I check shipping transit times?

We primarily use FedEx for standard ground shipments. You can view FedEx Ground Time-In-Transit information by entering our zipcode, 59047, at this page: https://www.fedex.com/ratefinder/home.

Shipping Services

Our online shipping prices are valid within the continental United States. For Alaska and Hawaii, please order using 2nd Day Air service. We are also happy to ship to you anywhere in the world. Please provide us the exact shipping address (street address if available), along with the quantity and product type you want to order, and we will let you know the additional shipping costs. Please note that some services are not available to all countries.

How can I get my order even faster?

Our standard service is quite fast. For most products we ship your order within 4 days after you approve your proof online, via FedEx Ground. In most parts of the country, that means you will have your order in about 6-10 days. If you want to receive your order faster, select one of our faster handling options or upgraded shipping options when you place your order.

How long will it take to get my order?

Most orders will be shipped within 4 business days after you approve your proof online. Please check the specific product ordering page for available turnaround times. Shipping by FedEx takes from 1 to 5 business days to get to you depending on your location.

How long does it take for me to get the proof of my job?

Once you have placed your order, you should get it within 1 business day after we receive your electronic files.

Where can I get more information on file preparation?

Our technicians are always available to assist you during business hours. You can reach us by email at info@printingforless.com and by phone at 800-930-6040.

Where can I get some more tips on designing a brochure?

Easy! Check out “How To Make A Super Brochure Or Mailing Piece”

How should I lay out a piece to comply with USPS mailing regulations? Do you have postcard and brochure templates?

Please see our postcard templates and brochure templates that have mailing requirements on them. Also, please give us a call at 800-930-6040 for further information.

Do you have templates to help me correctly design my project?

Templates are available on some of the product ordering pages. Our Design Templates page has a list of currently available templates. Look for more in the near future.

Where can I get more information on file and image resolution?

Our Resolution page has a comprehensive explanation of resolution and tips on how to properly prepare images to achieve the best quality printing.

How can I tell what resolution the image from my digital camera is?

Some digital cameras will let you know what the image resolution is, while others will tell you what the pixel dimensions of your image are. If you know what the pixel dimensions of your images are either from the camera itself or through the image editing software, you can do a little math to determine the resolution, and the size you can print the image at for clear and crisp printing.

Simply write down the pixel dimensions of your image and divide those numbers by 300 if the image does not include text and 400 if the image does include text. For example: An image without any text has a pixel dimension of 600 x 900 pixels. Once each dimension is divided by 300 the result is 2 x 3 inches. This means that you can use this image at 2 x 3 inches or smaller in your layout for quality printing results.

If your image editing software does not tell you what the pixel dimensions are, but it does tell you what the resolution is, then you know the maximum size you can use that image in your layout. We recommend that images be at 300dpi in their final size in the layout and 400dpi if the images include text. Please keep in mind that resolution and physical dimensions are in direct proportion to each other. If you have an image that is 2×2 at 300dpi and increase its size in the layout to 4×4 the new resolution is now 150dpi. So remember, when you bring an image in to your layout you can shrink it down in size (because the resolution will increase) but you will be limited as to how far you can increase it in size. See our Resolution page for more information on image resolution.

How should I take pictures with my digital camera?

Digital cameras are wonderful tools that allow us to capture our images in many different ways. The camera is designed to actually take three pictures; one in red, one in green and the other in blue (similar to the way a projection TV works). It then combines the colors together and saves the image onto the picture card. It is very important to make sure that the camera is set to the highest quality setting possible. This means that if you can only save one image on the picture card instead of 12, 64 or 128 images, then this is good! You want to create the best quality picture that the camera can make. This will mean large file sizes and slow downloads from the camera itself, but it will get you the best possible results from your camera. Remember, images should be at 300dpi in their final size in the layout!

More often than not, we notice that images that come from digital cameras print darker than expected on the printing press. Check to see if you have a brightness option in your image editing program to lighten the entire piece. If you have the opportunity to change the color space from RGB (red, green, blue) to the printing press colors of CMYK (cyan, magenta, yellow, black), then do so! It is always better to have you change the color space if you can, than for us to do it. Remember, not all colors that you can see that are created by elements of light (RGB) can be created by the elements of ink (CMYK) on press. If you do not have this capability with your software, do not worry about it, we will change it for you for free! Finally, we recommend that you apply a little sharpening to the image. This will make the image a little crisper and will print better on press.

Do I need to impose my business cards 8-up or 10-up if they will be printed more than 1 to a sheet?

No, send us a single layout of your job unimposed, we will handle any imposition needed on our end.

How much bleed should I have for an envelope?

1/16 inch is the correct amount, since it will wrap a little to the back of the envelope.

How do I check for proper imposition or backup?

“Imposition” and “backup” refer to how the front of a printed piece is oriented to the back. In the case of a brochure, you normally turn it over right-to-left (like you turn the page of a book) in order to have the back side read correctly — not upside down. Seems simple, until you get to a postcard where one side is layed out in landscape (horizontal) orientation, and the other side in portrait (vertical) orientation. We use our best judgement when imposing a job, so that it backs up in the most natural or normal manner. Some designs, however, contain both portrait and landscape elements on both sides, making it difficult to make a clear call. When reviewing your proof online, we will always post the front and the back in the orientation that they will print in relation to each other. So, if page 2 appears upside down, that is how it will be printed on the back of page 1. (Some people want it that way, so that the recipient of the piece must turn it over top-to-bottom in order to read it correctly.) Be sure to print out a copy of your online proof, and attach the two sides to each other to create a “mockup” or “dummy.” This is especially important when a job will be folded.

If I’m sending a Publisher file, should I compress it with “Pack and Go,” or should I just send the normal *.pub file?

While we can work with either type, we prefer to get the normal, uncompressed file. Please do not use Publisher’s “Pack and Go” feature. If you are sending Publisher files with linked graphics (generally NOT recommended in Publisher), please gather all the associated files into a single Zipped file, and send us that. Compressing files with Winzip or PK Zip (or StuffIt on the Mac) is also the preferred method for Quark, Pagemaker, Illustrator, InDesign or any file with linked graphics. If you are using a font that is not included with Publisher, please send it along with your Publisher file. You can either Zip them together, or upload the font as an additional file upload (or include it on cd or zip-disk if you are sending files via mail.)

Will you match a sample I print out on my own printer, or a previously printed sample?

At PrintingForLess.com, part of the way we offer fast turnaround and low pricing is by printing to a “pleasing color” standard, using standard ink densities. Therefore, there is no guarantee that your finished piece will approximate your printed sample. This is due in part to the widely varying results from different output devices including inkjet and laser printers, continuous tone proofing devices, high-resolution film-based proofs, and different than true offset lithography. Even from one commercial printing firm to another, there can be significant differences in results. In particular, inkjet and laser prints are known to look substantially different than true offset lithography.

If you require precise color match, please contact us to arrange for a digital color proof.

Once you approve the additional fees (starting at $40), we will produce and send you a hard proof via overnight delivery. When you approve and return the proof, we will strive to match the color of the proof when printing your final piece.

There are substantial additional charges for precise color match service. Also, if you request color correction or other changes after you see your proof, there will be a minimum of another $40+ charged for color correction time and a new proof.

Bottom line: the final product we produce for you is unlikely to match the output from your inkjet — it will look more professional!

How can I know what a particular CMYK color combination will look like?

To purchase a color guide with over 3,000 process colors with their CMYK screen percentages, please visit CreativePro.

What is the difference between the RGB and CMYK color space and why does it matter?

GB refers to the primary colors of light, Red, Green and Blue, that are used in monitors, television screens, digital cameras and scanners. CMYK refers to the primary colors of pigment: Cyan, Magenta, Yellow, and Black. These are the inks used on the press in “4-color process printing”, commonly referred to as “full color printing”.

The combination of RGB light creates white, while the combination of CMYK inks creates black. Therefore, it is physically impossible for the printing press to exactly reproduce colors as we see them on our monitors.

Many programs have the capability to convert the layout/images from the RGB color space to the CMYK color space. We request that you convert your colors from RGB to CMYK if your tools allow you to. By doing it yourself, you have maximum control over the results.You may notice a shift in color when converting from RGB to CMYK. If you do not like the appearance in CMYK, we recommend that you make adjustments while working in CMYK (usually lightening). Generally, you should specify CMYK color builds that look a little lighter than you want, since the dots of ink “fatten up” on press, giving you more pigment on paper than you see on your monitor. Be especially careful to keep backgrounds light if there is black or dark colored text over it, so that the text remains readable. See our RGB and CMYK Information page for more details.

How well will my job match what I see on my monitor?

Most people are surprised at how well their job matches what they see. But because of wide differences in monitor calibration and the different technologies used, some printed colors may not exactly match the colors on a your specific monitor. We do our best to make your job look good. See our design hints page for a more technical description.

What other file formats can you take?

We can take any Mac or PC version of Quark, Pagemaker, InDesign, CorelDRAW!, Illustrator, Photoshop, Freehand, Publisher, Word, PowerPoint, any file output as a PDF or listed on our File Formats page.

Can I send you documents created in MS Word or PowerPoint?

Absolutely! If you have created documents in Word or PowerPoint that contain photos, clip-art, or other color images, send them in. Same great service, same great pricing.

Can I order 2-color printing from you?

We suggest you get the best value for your dollar and go for full color, instead of two-color!

Nonetheless, you may use any of our product pages (with the exception of postcards, business cards, presentation folders, catalogs and calendars) to order two-color printing. Simply place your order as usual, then specify in the comments section that it’s a two-color job and what PMS colors you have selected. Since we are so efficient at producing high-quality four-color work, two-color pieces will be priced the same as four-color pieces. Two-color postcards, business cards, presentation folders, catalogs and calendars will generally be converted to four-color process equivalents before printing. If you need to produce 2-color business cards or postcards using spot inks, you can request a printing price quote online. Learn more about 2 Color Printing.

What is the Printing for Less Affiliate Program?

The Printing for Less Affiliate Program is a community of internet enthusiasts and entrepreneurs who promote Printing for Less products and earn commissions while doing so. The Program is a great way to earn cash and introduce your website visitors to the quality printing services offered by Printing for Less. The Printing for Less Affiliate Program compensates Affiliates with a commission for all initial and recurring orders placed within 90 days of the visitor’s first click through to PrintingforLess.com. Printing for Less Affiliates receive monthly commission checks and are given access to powerful tools that help to optimize and Affiliates’ efficacy and profits! You can find more information and sign up.

What about privacy and security?

No information we collect for order processing or from inquiries is shared with any other company or website. Your information is only used to contact you when necessary. Credit Card information is only used to bill you for products and services ordered.

What is your phone number and operating hours?

You can call us at Printing for Less at 866-501-7488 or 406-222-2689 from 8am to 5pm MST Monday through Friday. You can send an email at any time.

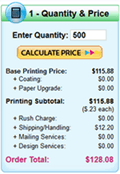

Our full-service website offers the first instant printing price quote system available for online printing, serving over 150,000 satisfied print customers since 1996. Get prices for dozens of standard printing products by experimenting with different quantities and options in the InstaPrice® Calculators located on the individual product pages accessible from the menu on the left side of this page and most pages on the site.

Our full-service website offers the first instant printing price quote system available for online printing, serving over 150,000 satisfied print customers since 1996. Get prices for dozens of standard printing products by experimenting with different quantities and options in the InstaPrice® Calculators located on the individual product pages accessible from the menu on the left side of this page and most pages on the site.