Specialty Printing Options

The following list is just a short overview of the types of specialty printing we offer. If you have something in mind that you don’t see here, give us a call, we are easy to work with!

- Die Cut Printing: We offer a set of standard die cuts for your convenience. We can also manufacture any shaped die cut you need for 100% customization.

- Customized Envelope Printing: Ready to make your envelopes gain customer attention and beg to be opened? We are your printer. We offer full bleeds with the entire envelope custom printed to meet your specifications.

- Foil Stamping and Metallic Inks: Hot foil stamping gives you a “mirrored effect” with reflective silver, gold, or full color options. Metallic ink is not as reflective, but gives you a nice, metallic toned look.

- Embossing: Let your imagination go crazy. Our embossing and debossing can raise or indent any portion of your design. You can go for a more dramatic 3-D effect that gets noticed.

- Spot Varnish Printing: We can spot varnish any part of your piece to add an interesting visual dynamic. This effect makes a portion of your text or image highly glossed and reflective without covering the color.

- Wide Format Printing: We can print anything but the side of your building! We offer window perfs, decals, large format signage, vinyl banners and more.

- Direct Thermal Label Printing: We can print the thermal, strong stickers that you find on traditional meat and product labels.

- Scented Printing: We can incorporate scratch and sniff elements or scented ink. We also have specialty glue which can house your custom fragrance and be applied to the printed piece; much like the samples you open in your favorite magazine.

- Glow-in-the-Dark Printing: We offer the coolest glow-in-the-dark inks. Perfect for concert tickets, flyers, and back-stage passes! (500 minimum quantity)

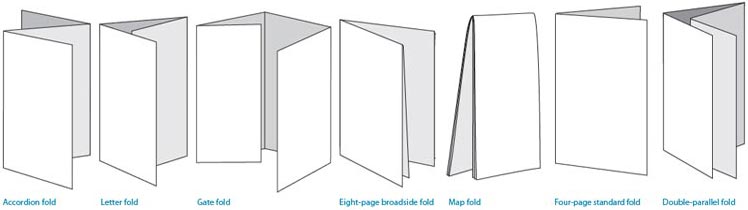

- Perforations and Folding Options: We provide tear-off perforations for any print piece you send our way. We also have numerous unique folding options which give you an economic way to add interest to your piece.

- Paper Options: We offer an array of specialty papers including magnetic paper, plastic paper, synthetic papers, recycled paper, heat resistant paper and textured paper.

Specialty printing is a snap with Printing for Less. We also offer Wire-O Binding, Variable Data Printing, Catalog Printing, Point-of-Purchase Displays, Floor Graphics, Notepad Printing, Calendar Printing, and much, much more.

We’re always up to a challenge. Bring us your ideas and let’s work together to get the results you envision!

What is sequential numbering?

What is sequential numbering? If you are thinking of using sequential numbering, please give our printing experts a call for helpful advice on how to best set up your artwork. We offer ready to use templates for the most common types of forms including invoice templates, statement templates, work order templates and purchase order templates. Just upload your logo and contact information and let us know how you would like to number your forms.

If you are thinking of using sequential numbering, please give our printing experts a call for helpful advice on how to best set up your artwork. We offer ready to use templates for the most common types of forms including invoice templates, statement templates, work order templates and purchase order templates. Just upload your logo and contact information and let us know how you would like to number your forms. When you need to make an impact, professionally bound materials are a great way to go. Saddle stitching is the perfect solution for smaller sized booklets and catalogs. Simple and cost effective, saddle stitching is an ideal method for binding booklets, magazines, notebooks, catalogs, programs, workbooks, calendars, menus and large brochures.

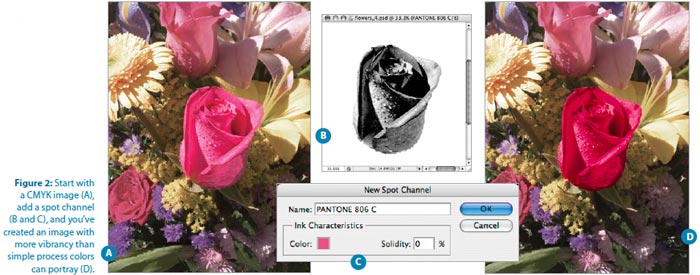

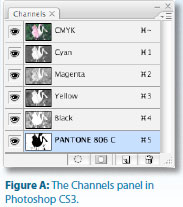

When you need to make an impact, professionally bound materials are a great way to go. Saddle stitching is the perfect solution for smaller sized booklets and catalogs. Simple and cost effective, saddle stitching is an ideal method for binding booklets, magazines, notebooks, catalogs, programs, workbooks, calendars, menus and large brochures. You probably know there are serious limitations on the gamut of colors that can be printed with combinations of cyan, magenta, yellow and black. But let’s pause for a moment of amazement at the range of colors that can be printed with CMYK. Think of all the color photographs that are successfully printed every day without the help of any special guest-starring inks.

You probably know there are serious limitations on the gamut of colors that can be printed with combinations of cyan, magenta, yellow and black. But let’s pause for a moment of amazement at the range of colors that can be printed with CMYK. Think of all the color photographs that are successfully printed every day without the help of any special guest-starring inks.

All of this is housed in a spiffy GoeCube storage and comes with access to the myPANTONE Web community for viewing and posting color palettes.

All of this is housed in a spiffy GoeCube storage and comes with access to the myPANTONE Web community for viewing and posting color palettes.